It is a necessary requirement by regulatory agencies for any product that is utilized by humans or animals to ensure microbial contamination. MLT is performed on a variety of pharmaceutical ingredients, medical devices, and non-sterile packaging from raw materials to the finished form of the product in order to determine the microbial load. Analysis is performed by our experts according to the strict guidelines and procedures outlined in USP<61>, USP <60> and USP<62>. USP<61>analysis quantifies the total aerobic microbial count and total yeast and mold count in a product being tested, while USP<62> allows for the detection of potential pathogens within a sample and USP <60> allows for the detection of Burkholderia cepacia Complex. Accuon Labs is capable to perform microbial limit testing as per USP <2021> and <2022> for nutraceuticals.

It is utilized to determine the effectiveness of preservatives added to nonsterile/sterile aqueous pharmaceutical products. These preservatives aid in preventing microbes that may inadvertently be introduced through the process of production or repeatedly withdrawing individual doses. The AET is also useful in determining whether the product’s preservative will maintain effectiveness throughout the shelf life or until expiration.

Completing the test requires inoculation of the product with a known quantity of various microorganisms. Effectiveness of the preservative is measured at varying times over the course of the next 28 days by comparing the known quantity of microorganisms introduced to the recorded quantities over the course of the testing period. We provide analysis for injections housed in multi-dose packaging, and for samples containing antimicrobial preservatives. Our scientists complete all analysis according to the processes and guidelines outlined within USP <51>, to ensure that all regulatory requirements are met for your product.

Environmental monitoring ensures the effectiveness of your cleaning and disinfecting processes and procedures. We are able to analyze the quality of air and surfaces within your manufacturing facility clean rooms and controlled environments following the guidelines set forth within USP<1116>. Our scientists can ensure that microbial levels will be controlled within the manufacturing environment allowing for confidence in the manufacturing of your product and reducing risk.

Following a comprehensive analyses, our experts will work closely with you in implementing an environmental monitoring program in order to keep your facility operating under the guidelines outlined under USP<1116>. We can provide you with a monitoring program that is all encompassing, ranging from, air, surface, and water quality, personnel training, and cleaning processes.

To verify the concentration of the active pharmaceutical ingredients (API) to determine the effectiveness of the product to inhibit growth of microorganisms. FDA regulations require that potency testing be performed on all products prior to release and that the potency specifications on the product label conform to the actual potency of the product. We perform all potency assays according to the processes set forth in USP<81> following cGMP standards. Methodologies we use in determining antibiotic potency include the cylinder plate and the turbidimetric assays. Strict controls are employed in both methods ensuring our clients they will receive the most precise and accurate reports following analysis.

Accuon is an expertise in microbiology testing & pharmaceutical testing, providing Endotoxin Testing services to detect and quantify gram-negative bacterial endotoxins by Chromogenic methods utilize a synthetic substrate which is added to the lysate. The reagent used by Accuon has the substrate co-lyophilized with the LAL reagent, which enables it to be used for all chromogenic methods. When chromogenic LAL reagents react with endotoxin, the cascade is initiated, and clotting enzyme is activated as in the other methods. The reactions proceed more rapidly at higher endotoxin concentrations.

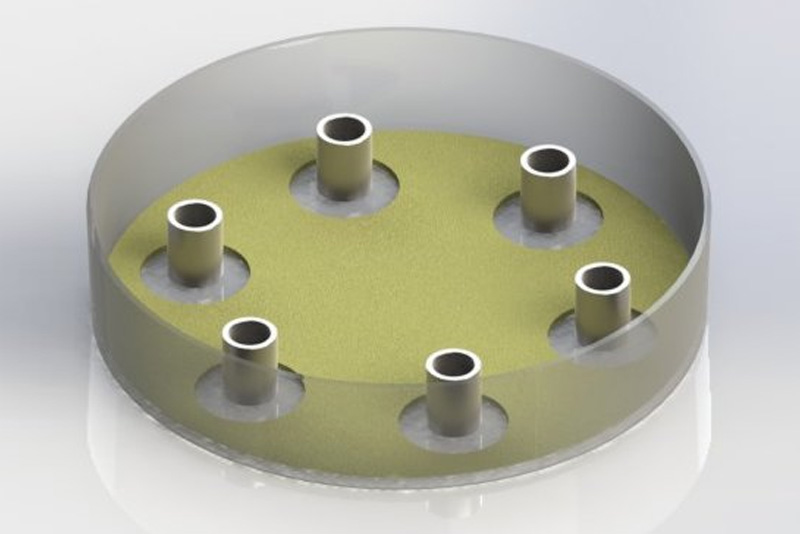

Accuon is using Sievers Eclipse instrument to detect endotoxin content in a sample while meeting all requirements of the harmonized pharmacopoeia: USP <85>, EP 2.6.14 and JP 4.01. Through groundbreaking technology, the Eclipse platform significantly decreases pipetting steps, reduces operator-to-operator variability, and simplifies assay setup. The Eclipse platform (Sensitivity down to 0.005 EU/mL) leverages precise microfluidic liquid handling and embedded endotoxin to automate kinetic chromogenic assays.

Accuon provides USP <71> Sterility Testing of sterile pharmaceutical products, medical devices and water. Sterility testing is required during the sterilization validation process as well as for routine release testing.

All sterile samples are prepared and inoculated in ISO 5 hoods in ISO 7 clean rooms, to eliminate laboratory contamination. We can test sterile product with Membrane filtration and Direct inoculation methods.

Accuon Labs performs growth promotion testing to confirm that each lot of media can support growth of the six microorganisms stated in USP <71> Sterility Tests.Prior to conducting a USP <71> sterility test, our laboratory performs method suitability for each specific product formulation to ensure that an appropriate method is chosen for testing.

© 2023 Accuon Labs Inc. All rights reserved.